Graphic Design Basics: How to Make Stickers, Part 1

So, you’re ready to turn your art and ideas into adhesive masterpieces and spend your entire paycheck on stickers? Rad! Making custom stickers is easier than you might think, but there’s more to it than dragging and dropping a random “PNG file” (thanks, Google) into the wizard at stickerapp.com.

Presenting part 1 of our How To Make Stickers guide for creating crisp, colorful, print-ready sticker designs that don’t just look good on screen but also shine IRL.

TL;DR:

-

Prep-work: Knowing the purpose and intended use, which material/s and products to order, takes your design from a sticker into a statement.

-

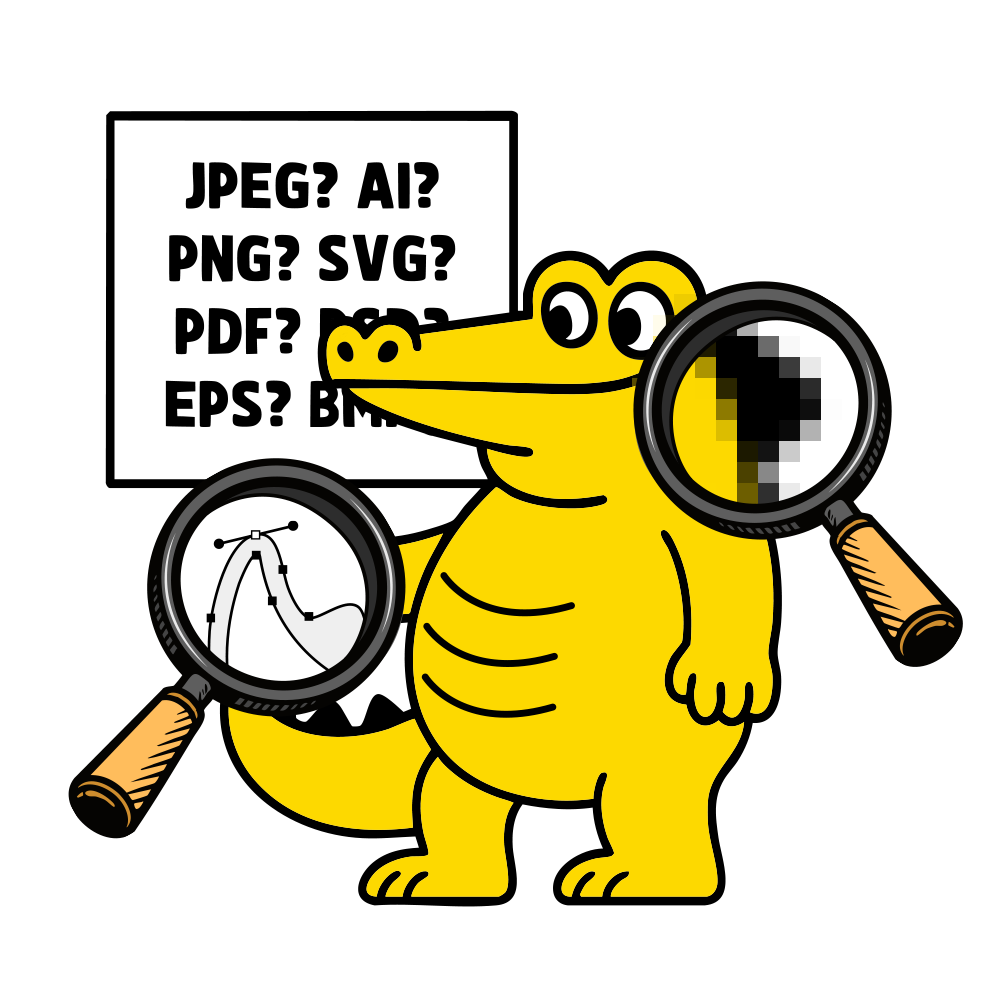

Vector > raster: Vectors (AI, SVG, EPS) scale without losing quality. Raster (JPEG, PNG) can get pixelated if not high-res.

-

Resolution matters: Always aim for 300 dpi at the actual print size to avoid fuzzy prints.

-

CMYK > RGB: We print in CMYK, so always design in CMYK for best results.

-

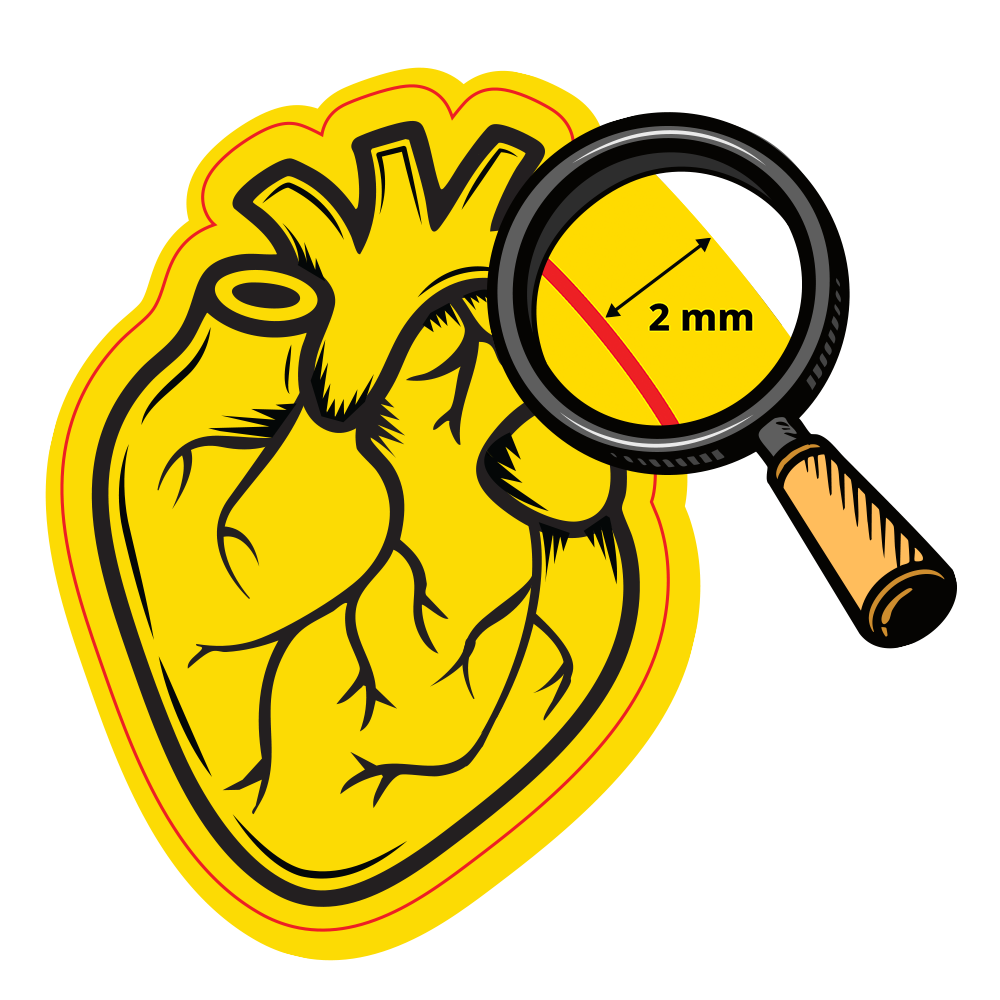

Beware of bleed: Add a 0,76"/2 mm bleed around your design and keep important elements 2 mm inside the cutline.

Prep-work: The Why/How/What of sticker making.

Designing stickers doesn’t mean you have to stick to design principles or adjust your art style to fit the purpose. No, nuh-uh! You do you, but we’d like to present some important factors and need-to-knows before you’re ready to go vinyl.

Let’s dive in:

Sticker Purpose

What is the intention of your stickers? Do you have something to say or want to make a statement? Are you looking to create sticker versions of your art, prints, and photos? Or use them as branding assets or for business purposes? Knowing the purpose helps define the “how-to”.

Sticker Usage

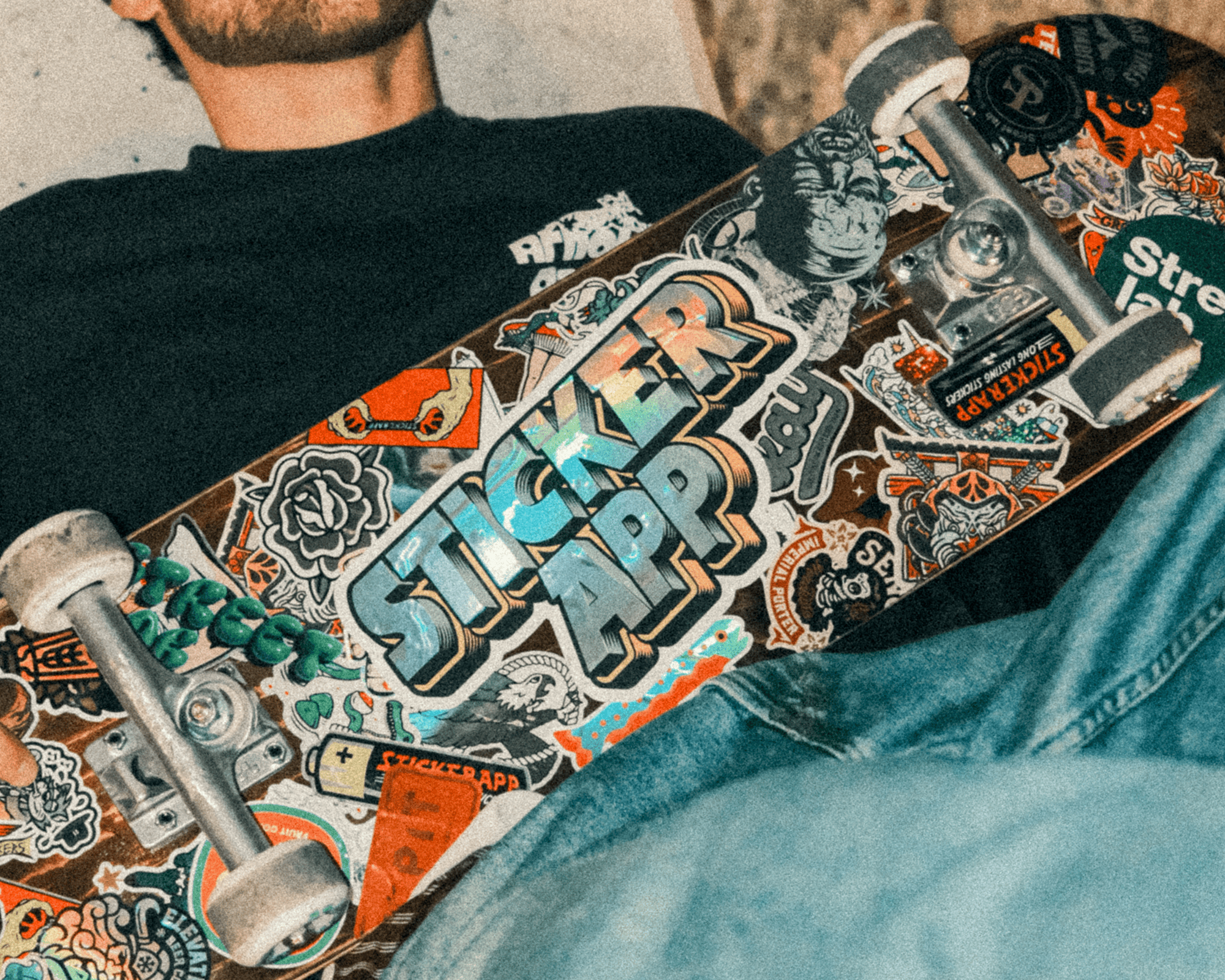

How do you plan to use your stickers, and where? Will they serve as freebies along with customer orders, will you hand them out at events, or simply slap them in public restrooms? (Disclaimer: We don’t encourage littering.) Determine the use for the best material and product selection (more on that below!).

Sticker Materials

Look, we’re not here to tell you what to do, but choosing the wrong sticker material is kind of like wearing stilettos to a hiking trip. Or rain boots to a wedding. Technically possible, but definitely not the vibe. Opting for a glittery unicorn sticker for your kid’s birthday party is, in fact, more suitable than a heavy-duty one. But by all means, prove us wrong.

Sticker Products

Some products are better suited for business than others, depending on your needs. Kiss-cut stickers can easily double as business cards, hang tags are great for your merch, labels on roll work perfectly for product labeling, and die-cut stickers - well, they work for any occasion.

Remember:

A great sticker design isn’t just cool. It’s spot-on, customized, and printable.

And speaking of printing…

Raster vs. Vector: What’s the Difference?

This might sound a bit nerdy, but it’s super important.

-

Raster graphics (like JPEGs, PNGs, and GIFs) are made of pixels. That’s fine for web use, but blow it up too much and boom: pixel problems.

-

Vector graphics (like SVGs, AI, or EPS files) are based on math, not pixels. That means they scale to any size without losing quality. Whether your sticker’s the size of a penny or a laptop, vectors stay sharp.

As a sticker printing company, we want the best for your stickers! We love vectors because they keep your designs looking sharp, no matter the size. If you’re using raster artwork, ensure the resolution is high enough (hint: we’re JUST about to touch on this topic...).

High-Resolution vs. Low-Resolution Artwork

This one’s easy. Resolution = how detailed your image is.

-

High-res (300 dpi or more): Perfect for printing.

-

Low-res (under 150 dpi): Risky business. Might end up a blurry, pixelated mess.

Your screen might make a 72 dpi image look alright, but printers? Not so forgiving. Always aim for 300 dpi at actual print size to keep your stickers looking sweet.

Pro tip: If you have to scale your artwork up a lot, it’s probably too low-res. Start with big files to avoid heartbreak.

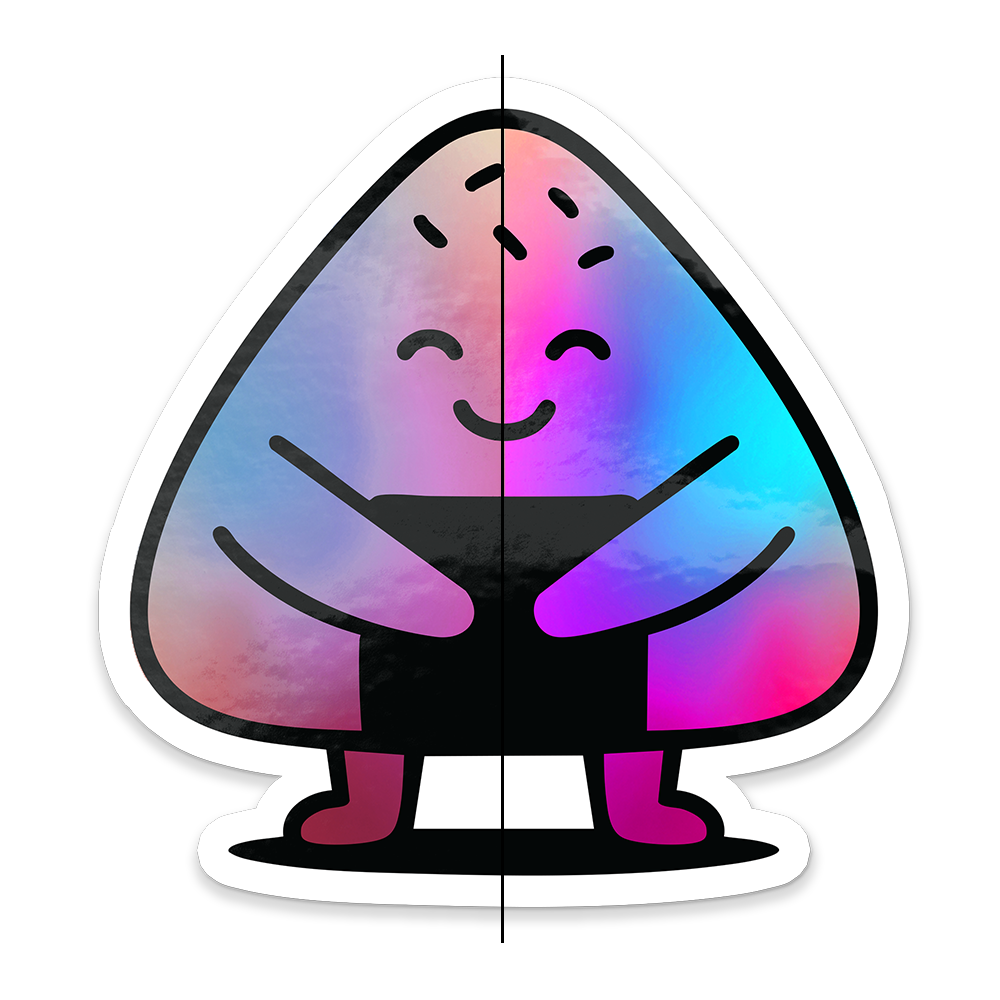

RGB vs. CMYK: Let’s Talk Color Modes

RGB and CMYK might sound like robot names, but they’re actually how colors are created on different platforms.

-

RGB = Red, Green, Blue. This is your screen's jam.

-

CMYK = Cyan, Magenta, Yellow, Key (Black). This is how printers roll.

Here’s the kicker: We print in CMYK, so if your design is in RGB, colors might shift slightly when printed. Think neon green turning into a murky lime.

Always design in, and save your files to. CMYK before uploading for the most accurate print preview. That way, the colors will be true to the design, and your bubblegum pink will stay bubblegum-y.

Be wary of Bleed

Nope, not a horror movie reference. Bleed is a printing term, and it's super important if you want to print stickers without borders.

What is bleed? Bleed is the extra 2 mm of your design that extends beyond the sticker’s cutline. Why? Because printers aren’t perfect. That 2 mm ensures that your design covers the whole sticker, edge to edge, even if there’s a slight shift during cutting.

-

Always add a 2 mm bleed to your design if you want your stickers without borders.

-

If you want borders, don’t worry! They are automatically added when the file is uploaded to the sticker maker.

Bonus tip: Don’t put text or logos right near the edge. Keep key stuff at least 2 mm inside the cutline too; that’s your safe zone.

Final Checklist Before You Hit Upload

Here’s your no-nonsense, stick-it-on-your-wall checklist:

-

File type: Vector (AI, SVG, EPS) or high-res raster (300 dpi)

-

Color mode: CMYK

-

Bleed: 2 mm all around (if you want stickers without borders)

-

Resolution: 300 dpi at actual sticker size

-

Safe zone: Keep text + logos 2 mm inside the cut line

Vibes: On point.

Eager To Learn More?

Don’t miss the other parts of the How to Make Stickers series! Follow the links below to catch up on previous posts or continue reading.

)